What is the best wind resistant beach umbrella?

Posted by Admin

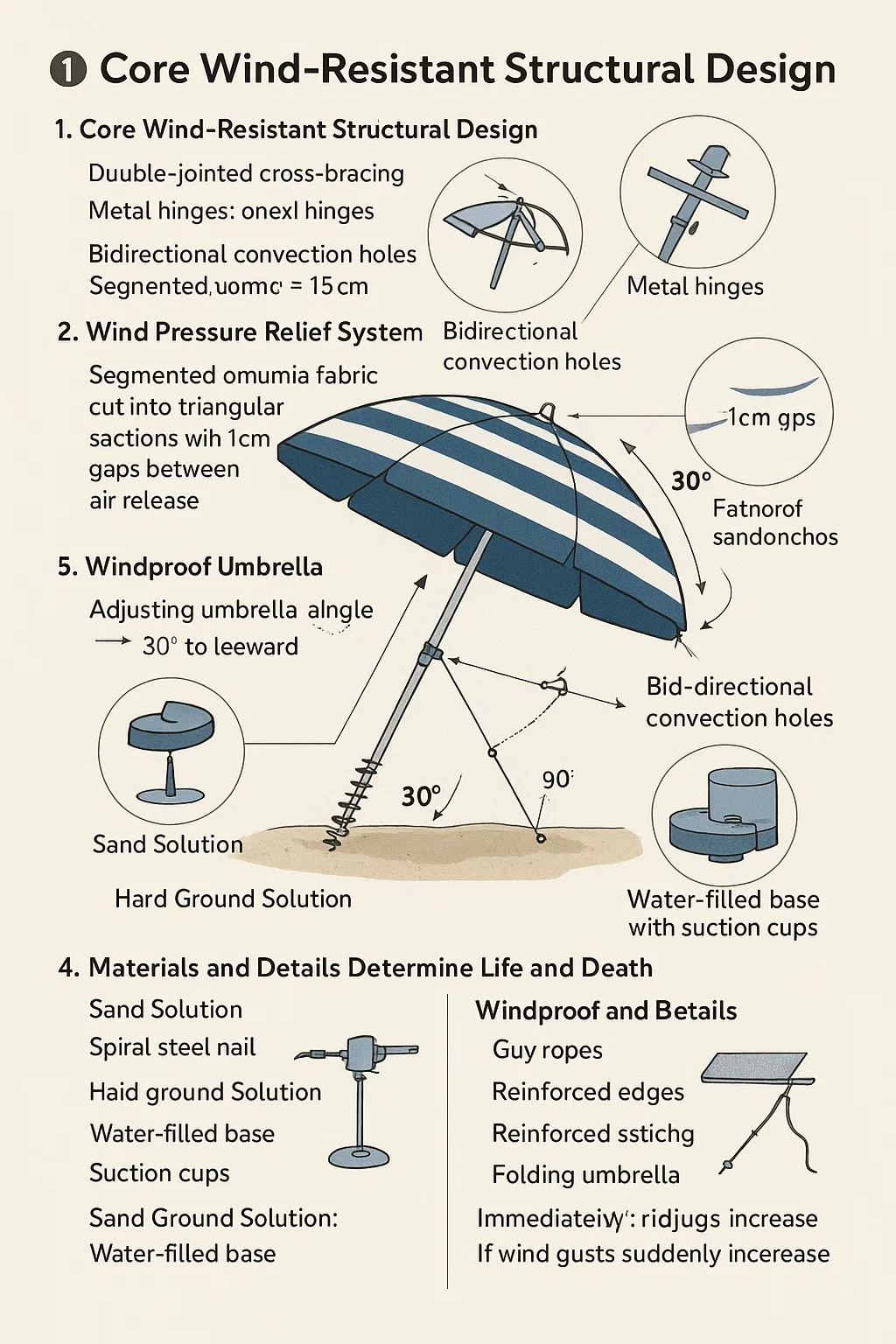

Choosing a beach umbrella with excellent wind resistance requires focusing on its structural design and wind-resistance mechanisms, avoiding flashy promotional gimmicks. Key considerations include:

1. Core Wind-Resistant Structural Design

Umbrella Joints: Choose a double-jointed cross-bracing (X-shaped structure), which increases load-bearing capacity by over 50% compared to a single-jointed structure. Avoid plastic connectors—metal hinges with rivet reinforcements are essential for wind resistance.

Umbrella Shape: A curved dome (not a flat surface) guides wind away from the sides, reducing stress on the umbrella. Flat umbrellas can easily become "sails" and flip over in a 30-second gust.

2. Wind Pressure Relief System

Top Ventilation: Bidirectional convection holes (diameter > 15cm) are essential to ensure wind passes through the umbrella, rather than lifting it. Inferior vents are merely decorative—they only work if you can insert a finger.

Segmented Umbrella: The umbrella fabric is cut into 6-8 triangular sections, with 1cm gaps between them for air release (similar to the principle of sailcloth).

3. Practical Performance of the Anchoring System

Sand Solution: Spiral steel nails (thread depth > 30cm) + anti-torsion crossbar (insert into the sand, rotate the crossbar to lock). Ordinary straight nails can loosen easily in crosswinds.

Hard Ground Solution: Water-filled base (capacity > 15L) with suction cups on the bottom for anti-slip protection. After filling with water, attach a weight bag to enhance rollover resistance.

4. Materials and Details Determine Life and Death

Rib Material: Fiberglass > Aluminum Alloy > Iron (iron pipes at the seaside are prone to rust and breakage in salt spray). Ribs should have a slight spring back when pressed; too rigid will break easily.

Cloth Treatment: High-density polyester impregnated with waterproof glue (feels slightly hard). Cheaper fabric will be soft and floppy.

Stitching: Rib ends are reinforced with ribs and the edges are taped with glue - tears often originate from the thread holes.

5. Windproof Umbrella Umbrella Umbrella Angle

Adjustment: In strong winds, tilt the umbrella 30° to the leeward direction (with the ribs parallel to the wind direction) to reduce the area facing the wind. Emergency reinforcement: Use guy ropes to tighten the umbrella handle in three directions. Anchor with sand anchors, rocks, or camping spikes.

Danger warning: If the wind gusts suddenly increase, immediately fold the umbrella—this is a windproof umbrella, not a typhoon umbrella.

| Feature | Wind-Resistant Design | Weak Designs to Avoid | User Tips |

| Frame Joints | X-cross double hinges with metal rivets | Single plastic joints or flimsy clips | Twist joints manually pre-buy—no wobble or squeak |

| Canopy Shape | Curved dome (wind slides sideways) | Flat or shallow-angle canopies | Look for 35°+ arc—resembles a turtle shell |

| Ventilation | Top vent >15cm + side gaps between panels | Tiny decorative holes or no vents | Finger test: entire hand should pass through vent |

| Anchor System | Sand: Deep-spiral steel stake + locking crossbarHard ground: 15L+ water base + rubber grip pads | Short straight stakes or hollow plastic bases | In sand, twist stake until crossbar touches ground |

| Pole & Ribs | Fiberglass ribs (flexes, not breaks) + powder-coated steel pole | Thin aluminum ribs or painted iron (rusts) | Saltwater test: Rinse pole; rust spots within 1 hour = reject |

| Fabrics & Stitching | Ripstop polyester + taped seams + triple-stitched stress points | Untaped seams or thin nylon fabric | Tug fabric near seams—if threads gap, skip |

| Wind Tactics | • Tilt 30° into wind• Triple-guylines to anchors• Close if gusts >25mph | Keeping upright in strong crosswinds | Carry spare sand anchors & paracord |

| Myth Bust | "Heavy = stable" → Structure matters more than weight "Auto-open" → Manual open/close survives more seasons | Trust brands tested by surfers/coastal resorts |